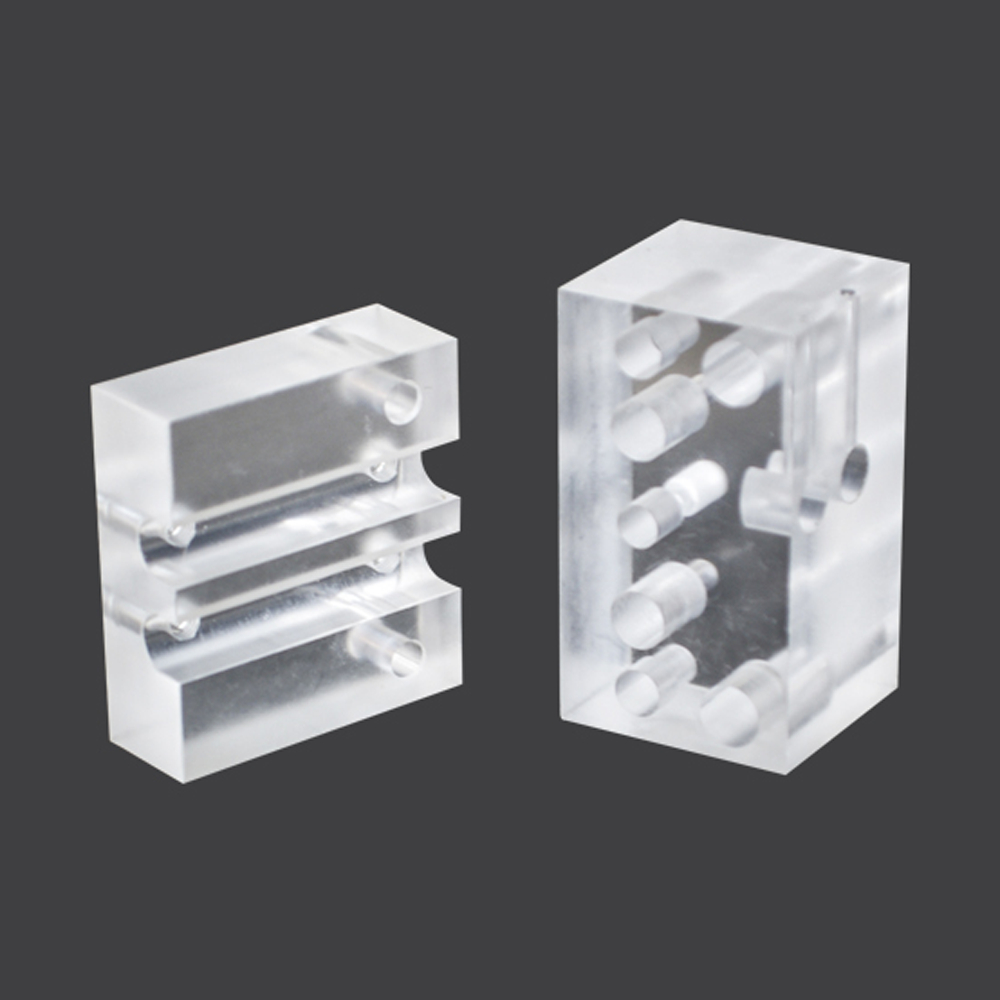

| Name: | Custom Machining Plastic Parts |

|---|---|

| Tolerance: | from +/-0.02 |

| MOQ: | 1 Piece |

| Drawing Format: | 2D/(PDF/CAD), 3D(IGES/STEP) |

| Quality control: | 100 Inspection |

| OEM/ODM: | Accecpted |

| Lead time: | 7~25 Working Days |

| Sample: | Within 7 Days |

| Processing Type: | 3 Axis CNC Machining |

| Place of Origin: | Shanghai, China |

Product Description

Hereby affirm

Flytigercnc guarantees that it will not show customers' product designs and finished products in private. Protect customer privacy and rights. FytigerCNC could sign the NDA before customer send the drawing.

FlytigerCNC forbidden produce any lethal weapons!!!

Our Value : "To Warm The World With Machinery".

World need peace ! not war !

Quickly Get Quote:

Before offer the price. Get the quote simply by completing and submitting the form below:

• Attached 2D or 3D design_______( We accept IGS, IGES, STP, STEP, SLDPRT, 3D DWG, 2D DXF, PDF)

• Material:________

• Quantity: ________pcs

• And many kinds details. Finishes, tolerance,Hardness and more.

• Where to Shipping: ________(Country with postal code please)

| Quickly turn around | Many kinds of machines, highly accurate parts in as little as 6 business days. |

| Multiplicities | We could make the plastic welding, 3-Axis Machining, 4-Axis machining, Turning, Chucking, Threading, Milling, Tapping, Drilling. |

| PRECISION | Offers high-precision tolerances ranging from +/-0.001″ – 0.005″, depending on customer specs. |

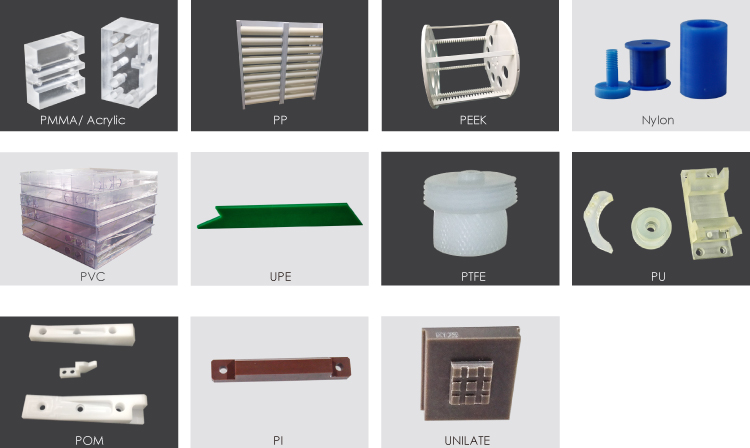

| MATERIAL SELECTION | Choose from over 10 plastic materials. CNC Machining offers a wide variety of certified materials. |

| Minimum Order Quantity | 1 piece. We believe the customer will place a large order for us after they know our quality. |

| One- stop Service | we could make the stamping parts, laser cutting parts, Casting parts, forge,casting, 3D printing etc. |

| Sample | We accept 1pciece sample. And if the sample design is easy making, we could free for you. |

| Engineer | When you bring a design, drawing or concept for a product that you need manufactured, our designers and engineers will make sure that all of the dimensions are right and that the correct materials are used to stand up to the practical applications of the part, tooling or machine you need. |

| After-sales service | If your order or our sales have any dissatisfactions. Please send the email to top@flytigercnc.com. We will reply to you in 12 hours. We Guarantee, if it is our mistake, we will free redo or full refund for you ! |

| Disadvantage | 1.Can’t reply in 6 hours every time. 2.Not rich English. Telephone communication is inconvenient 3.We are not a big company. but we will be. 4.The service is not perfect! |

Plastic machining Material & Tolerance & Finishes:

| Plastic | |

| Fiberglass | Acrylonitrile Butadiene Styrene (ABS) |

| Polycarbonate (PC) | Acetal (Polyoxymethylene (POM)) Delrin/Acetal |

| Polyetherimide (PEI) [Ultem] | Polyvinyl Chloride (PVC) |

| Polypropylene(PP) | Polyether Ether Ketone (PEEK) |

| Polyethylene (PE) | Polymethyl Methacrylate (PMMA/Acrylic) |

| Polyurethane (PU) | Polytetrafluoroethylene (PTFE) [Teflon] |

Machining Bakelite Part |

Machining Acrylic Part |

|

Machining Nylon Part |

Machining PEI Part |

Machining PEEK Part |

Machining POM Part/ Delrin part |

Machining ABS Part |

Machining PU Part |

Worried material quality?

-We can offer material certification, test report and related surface-treatment report;

We have contacted many customer feedback. They feel that FlytigerCNC's plastic machining products are relatively expensive. This is totally acceptable to us. Indeed, our plastic machined products are slightly higher than other factories in the Chinese market. Please carefully read the following processing technology, we will explain the reason to you at the bottom of the video

CNC Machining Capabilities

• 3 axis CNC Machining

We have 3 sets 3 axis machine center. Tolerance: ±0.02mm

• CNC routing

We have 4 sets route machine center. Tolerance: ±0.02mm

• NC Turning

1 set NC lathing machine. Tolerance: ±0.01mm

• high-temperature processing

We could provide plastic plate folding and welding service as well.

• Welding plastic parts processing

We believe you have watched most of the videos. The following are the aspects I want to explain, I hope you will read it carefully. Because we feel that customers spend their time and money doing business with FlytigerCNC. Don't send emails without knowing it.

1. All our equipment is of very good quality. Some are from Taiwan, some are from Japan, and some are from the United States. These equipments can process metal materials like 304 stainless steel. And plastic products are definitely not as hard as metal products. Therefore, during the operation of our equipment, the accuracy has been maintained at a very high level.

2. FlytigerCNC's plastic processing plant and metal processing plant are separate. Our plastic processing workshop does not allow any metal products to be processed. In China, such companies rarely do this. Many mechanical processing plants will mix processing. There are many hidden dangers. The simplest white Derlin machined product. If it is produced on mixed processing machinery and equipment, metal processing will produce a lot of grease. Finally, the white pollen has a lot of black grease, which is difficult to remove. Affect the beauty of the product.

3. Although there are not as many types of plastic products as there are metals. But there are actually many types. The characteristics of each material are different. The mechanics of our professional plastic processing workshop are very familiar with the characteristics of materials. They know which processing procedure can guarantee the accuracy of the product. Because plastic products are very affected by temperature and cutting procedures. The general factory does not understand the characteristics of the material and processes it in the same way as metal. In the end, the quality of the product was unqualified and was sent to the customer at will. This will cause great harm. We need very meticulous work to do mechanical processing. Once there is a problem with the quality of the product, the customer uses this component in an important position ,and the experiencer may suffer casualties in life because of our unqualified processing. In FlytigerCNC, this is not allowed!

4. The materials we commonly use are imported from Japan. Some special materials are purchased from well-known Chinese suppliers. Therefore, the material cost is much more expensive than ordinary factories. Non-professional factories randomly purchase a batch of materials from the market and process them directly. The surface color and feel are similar. In fact, the mechanical properties are completely different. The torque that can withstand is not a level at all.

Every product contains a story. Every business has faith. Just like FlytigerCNC, our company's mission is: To Warm The World With Machinery!

We can make cheap products, but we will not make cheap products. Because we guarantee our quality and warm the whole world.

If you have any question, please do not hesitate to let me know!

:-) It's a pleasure for us to serve you!

Related Products

Custom Drone Carbon ...

FlytigerCNC route machine could cutting carbon fiber for drone

Custom EVA foam Mach...

FlytigerCNC route machine could cutting carbon fiber for drone