Aluminum

Aluminum alloy is one of the most widely used non-ferrous metal structural materials in the industry and has been widely used in aviation, aerospace, automotive, machinery manufacturing, marine and chemical industries. With the rapid development of the industrial economy, the demand for aluminum alloy welded structural parts is increasing, and the research on the weldability of aluminum alloys is also deepened. Aluminum alloys are currently the most widely used alloys.

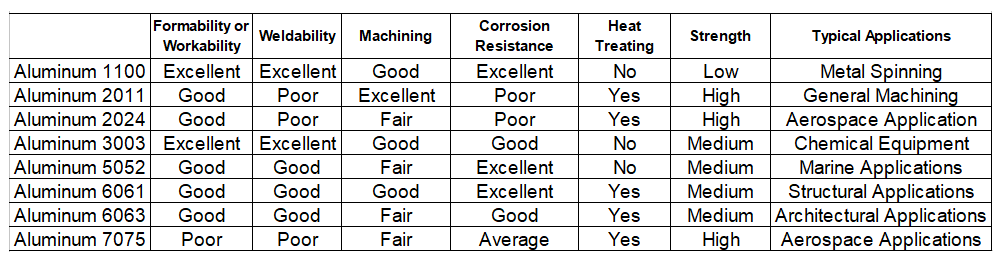

Aluminum 1100: Generally used in articles, heat sinks, caps, printing plates, building materials, heat exchanger components, and can also be used as deep drawn products. It is widely used in various fields from cookware to industrial equipment. The purity can reach above 99.00%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is a series commonly used in conventional industries.

Aluminum 2011: Are used in screws and machined products that require good cutting performance.

Aluminum 2024: Are commonly used in aircraft structures, rivets, missile components, truck hubs, propeller components, and other structural components. .

Aluminum 3003: Be called a rust-proof aluminum. Aluminum 3003 is composed of manganese as the main component and the content is between 1.0 and 1.5%. It is a series with better anti-rust function. Conventional applications in the humid environment of air conditioners, refrigerators, and car bottoms, the price is higher than the aluminum 1100 series, which is a more common alloy series. Used in kitchen utensils, food and chemical processing and storage devices, tanks and tanks for transporting liquid products, and various pressure vessels and pipes processed in thin plates. .

Aluminum 5052: It belongs to the more common alloy aluminum plate series. The main element is magnesium, and the magnesium content is between 3-5%. Also known as aluminum-magnesium alloy. The main features are low density, high tensile strength and high elongation. In the same area, the weight of aluminum-magnesium alloy is lower than other series, so it is commonly used in aviation, such as aircraft fuel tanks.

Aluminum 6061: With excellent interface characteristics, easy coating, high strength, good workability and strong corrosion resistance. Requires a variety of industrial structures with high strength, weldability and corrosion resistance, such as aircraft parts, camera parts, couplers, marine parts and hardware, electronic parts and connectors, decorative or various hardware, hinged heads, Heads, brake pistons, water pistons, electrical accessories, valves and valve parts.

Aluminum 6063: Commonly used in building profiles, irrigation pipes and extrusion materials for vehicles, gantry, furniture, fences, etc.

Aluminum 7075: It mainly contains zinc. Also belonging to the aviation series, it is an aluminum-magnesium-zinc-copper alloy, heat treatable alloy, which belongs to super-hard aluminum alloy and has good wear resistance. The 7075 aluminum plate is stress-relieved and will not deform or warp after processing. All the ultra-thick and ultra-thick 7075 aluminum plates are all ultrasonically detected to ensure no blisters or impurities. The 7075 aluminum plate has high thermal conductivity, which can shorten the molding time and improve work efficiency. The main feature is that the hardness of 7075 is a high hardness, high strength aluminum alloy, which is commonly used in the manufacture of aircraft.