What are the requirements for precision part processing?

The standards of the precision parts processing industry are very strict, and there are different process steps such as feeding and cutting. According to the requirements of the products, the processing precision requirements will be different. In general, the precision machining precision requirements are very high, sometimes even accurate to the micrometer difference. If the size is very different, the product will become a waste product, and rework is needed to achieve Requirements. Sometimes all raw materials are scrapped, resulting in an increase in costs. At the same time, parts are inevitably unusable, so there are many requirements for precision parts processing. So what are the requirements for precision part processing?

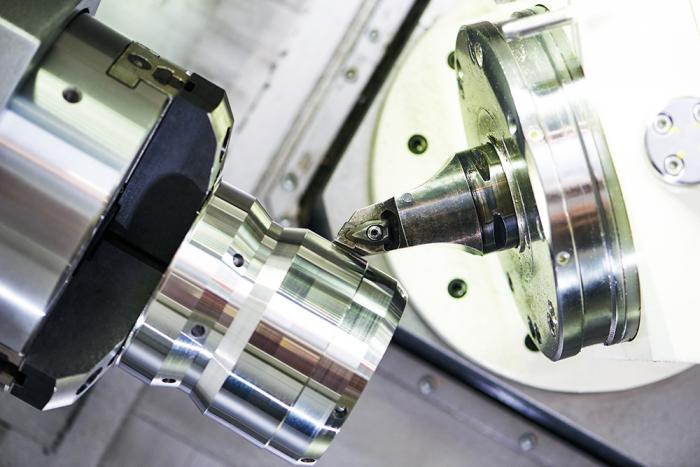

(1) Generally, in order to ensure the machining accuracy of the parts, the machining of the rough parts and the precision mechanical parts must be performed separately, because the cutting amount, the clamping force, the heat generation, and the cutting force of the workpiece are processed by the rough parts and the precision parts. Unlike the rough machining and precision machining, the precision of precision machined parts will be lost due to the difference in stress.

(2) The rationality of equipment selection. The processing of rough parts does not require high processing precision, but it mainly cuts the machining allowance, so precision machining requires machining with very high precision.

(3) In the precision parts processing route, heat treatment processes are often arranged. The arrangement of the heat treatment process is as follows: in order to improve the cutting performance of the metal, such as annealing, normalizing, quenching and tempering, etc., it is generally arranged before the machining of the mechanical parts.

In general, there are almost all heat treatment processes for precision part processing, and the heat treatment process can improve the cutting performance of metals.