| Name: | Custom CNC Machining |

|---|---|

| Tolerance: | from +/-0.001 |

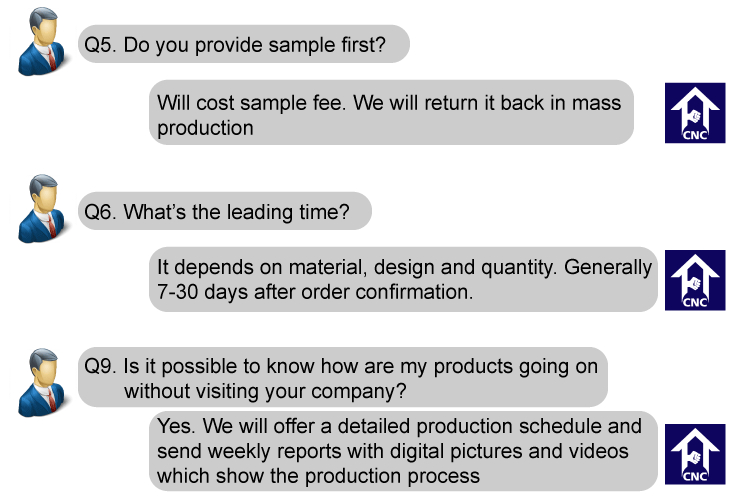

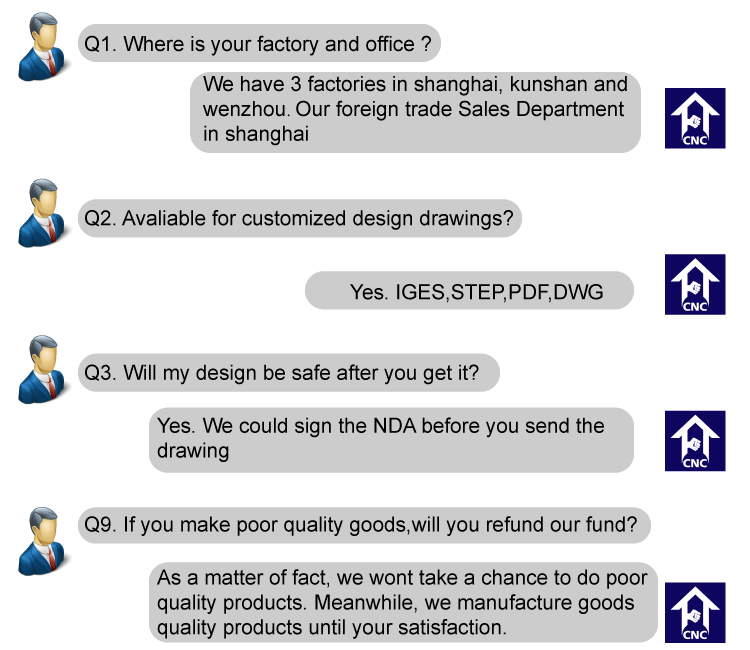

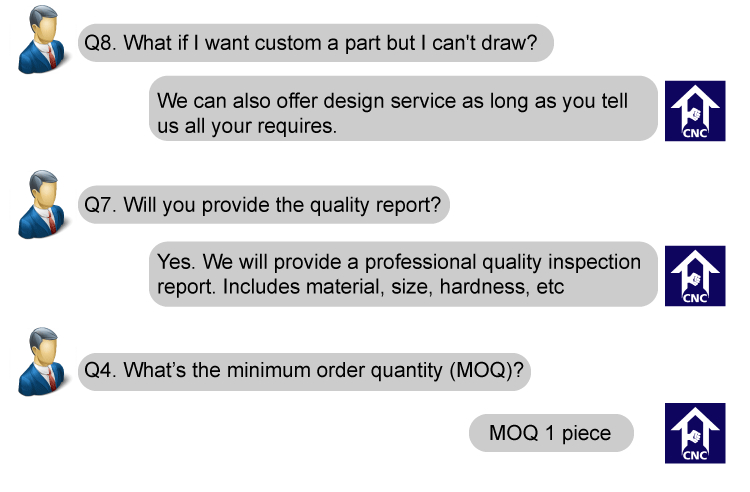

| MOQ: | 1 Piece |

| Drawing Format: | 2D/(PDF/CAD), 3D(IGES/STEP) |

| Quality control: | 100 Inspection |

| OEM/ODM: | Accecpted |

| Lead time: | 7~25 Working Days |

| Sample: | Within 7 Days |

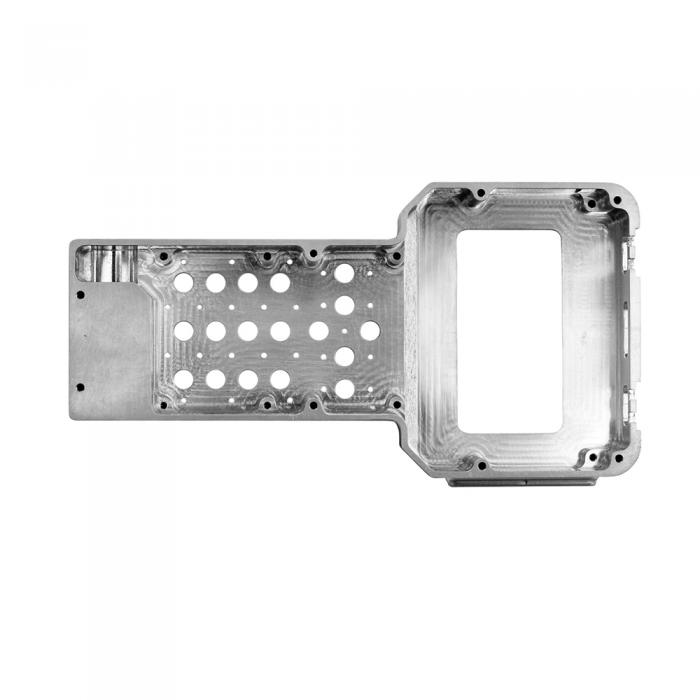

| Processing Type: | 3/4/5 Axis CNC Machining |

| Place of Origin: | Shanghai, China |

Product Description

Hereby affirm

Flytigercnc guarantees that it will not show customers' product designs and finished products in private. Protect customer privacy and rights. FytigerCNC could sign the NDA before customer send the drawing.

FlytigerCNC forbidden produce any lethal weapons!!!

Our Value : "To Warm The World With Machinery".

World need peace ! not war !

Quickly Get Quote:

Before offer the price. Get the CNC machining rapid prototyping quote simply by completing and submitting the form below:

• Attached 2D or 3D design_______( We accept IGS, IGES, STP, STEP, SLDPRT, 3D DWG, 2D DXF, PDF)

• Material:________

• Quantity: ________pcs

• And many kinds details. Finishes, tolerance,Hardness and more.

• Where to Shipping: ________(Country with postal code please)

| Quickly turn around | Many kinds of machines, highly accurate parts in as little as 6 business days. |

| Multiplicities | We could make the welding, 3-Axis Machining, 4-Axis machining, Turning machining, Chucking, Threading, Milling machining, Tapping machining, Drilling machining. |

| PRECISION | Offers high-precision tolerances ranging from +/-0.001″ – 0.005″, depending on customer specs. |

| MATERIAL SELECTION | Choose from over 50 metal and plastic materials. CNC Machining offers a wide variety of certified materials. |

| CUSTOM FINISHES | Ra3.2 to Ra0.8, Milled Finish |

| Minimum Order Quantity | 1 piece. We believe the customer will place a large order for us after they know our quality. |

| One- stop Service | we could make the stamping parts, laser cutting parts, Casting parts, forge,casting, 3D printing etc. |

| Sample | We accept 1pciece sample. And if the sample design is easy making, we could free for you. |

| Engineer | When you bring a design, drawing or concept for a product that you need manufactured, our designers and engineers will make sure that all of the dimensions are right and that the correct materials are used to stand up to the practical applications of the part, tooling or machine you need. |

| After-sales service | If your order or our sales have any dissatisfactions. Please send the email to top@flytigercnc.com. We will reply to you in 12 hours. We Guarantee, if it is our mistake, we will free redo or full refund for you ! |

| Disadvantage | 1.Can’t reply in 6 hours every time. 2.Not rich English. Telephone communication is inconvenient 3.We are not a big company. but we will be. 4.The service is not perfect! |

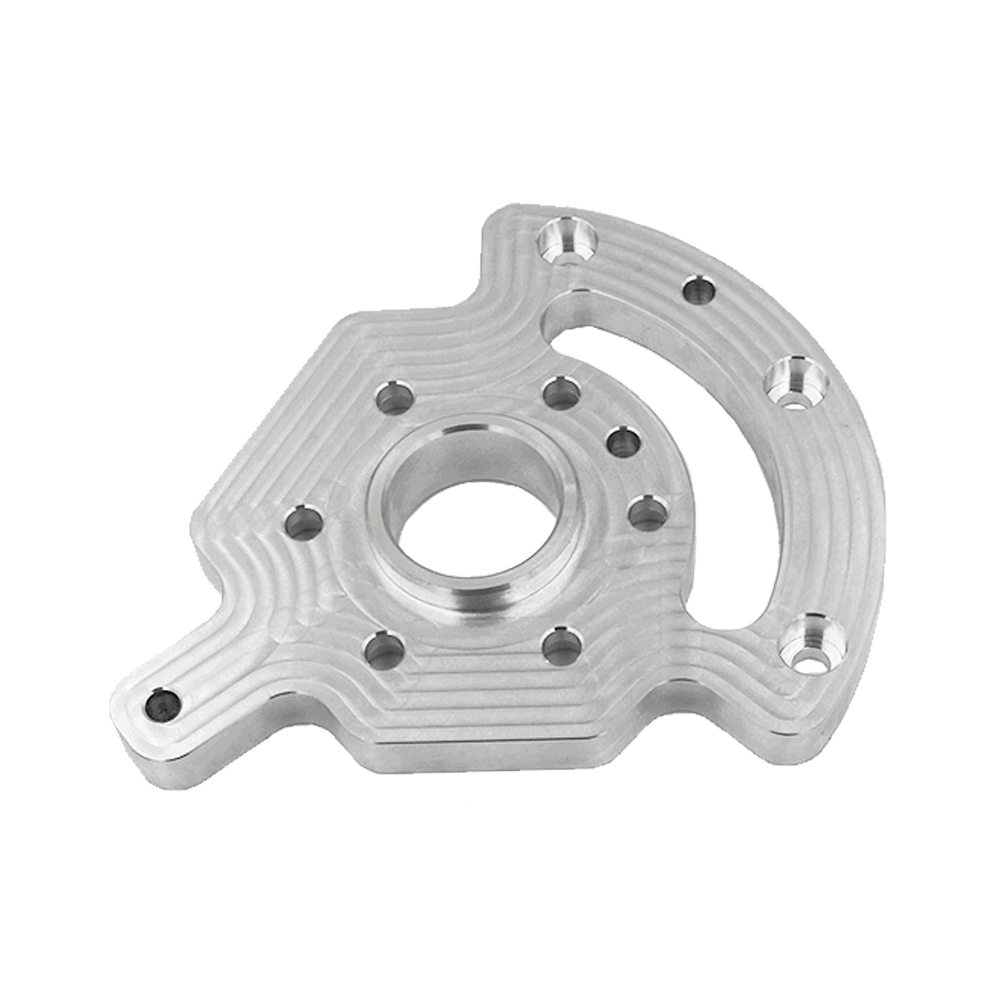

CNC Machining Capabilities

• CNC Turning

10 sets CNC automatic lathe, manufactured in China. Fast processing speed, complicated processing of parts in one time, accurate and reliable processing, automatic feeding, automatic shut down of material, and high production efficiency. Focus on φ3-φ20, length limited 150mm turning parts.

2 sets CNC automatic lathe, manufactured in Japan. Focus on φ1-φ20, length limited 200mm turning parts.

• 3 axis CNC Machining

1 sets vertical CNC gantry machining. Processing large-scale high-precision mechanical parts. X/Y/Z: 2000mm x 1000mm x 1000mm. Super high mechanical stability, can process various materials.

6 sets vertical CNC mill machining. we make your machined metal or plastic parts and get them to your door in as fast as 1 day.

PS: Our metal machining factory and plastic machining factory are two independent factories. Professional people do professional things, professional equipment produces professional products

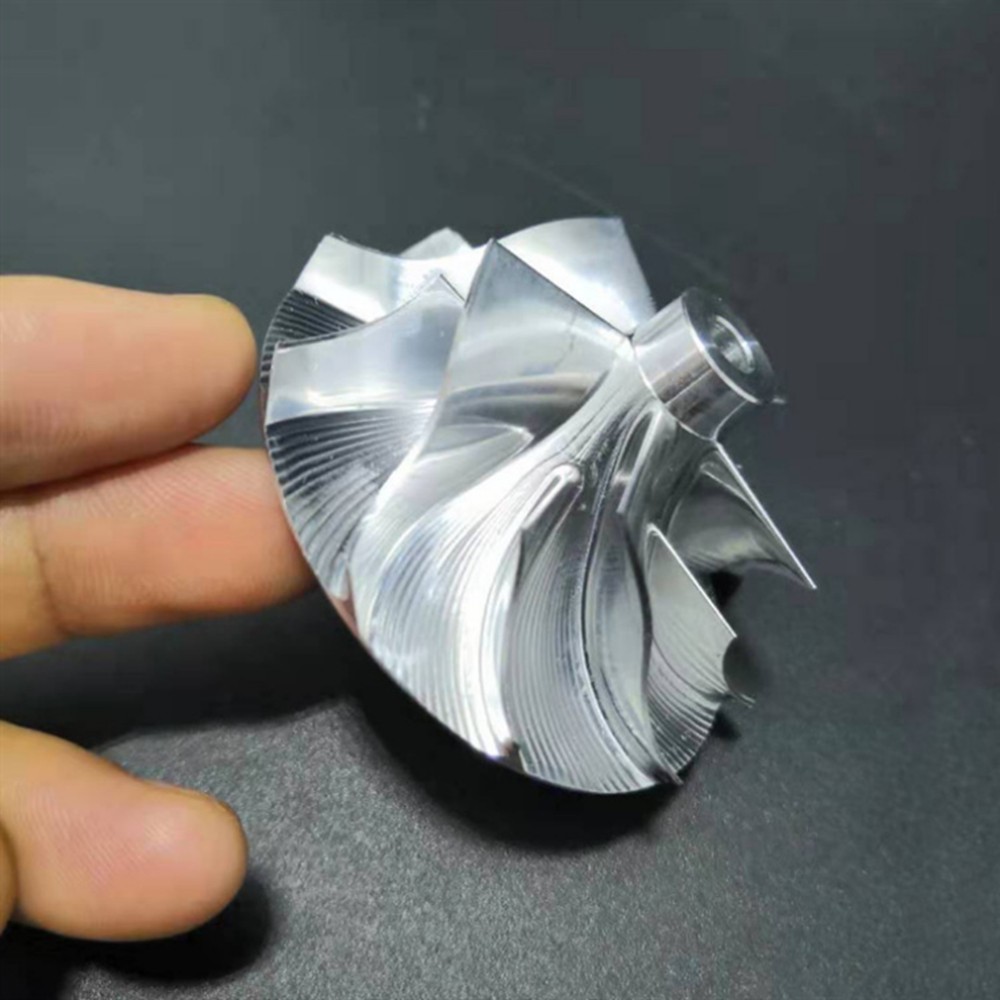

• 4 axis CNC Machining

2 sets Turning and milling compound machining. high rigidity, perfect precision, high speed.

• Wire EDM

8 sets wire EDM machining service.

CNC Machining Material & Tolerance & Finishes:

| Matels | |

| Aluminum | AL6061, AL6063, AL7075, AL6082, AL2024, AL5052, ALA380 |

| Brass | C36000, C37000, C37100, C37700, C32800, C26000, C24000, C22000 |

| Copper | C11000, C12000, C12200, C10100 |

| Stainless Steel | SS304, SS316, SS303, SS201, SS301, SS416 |

| Iron | 20#,45#,Q235,Q345,1214,1215 |

| Tungsten, Bronze, Titanium, Zinc, Magnesium, molybdenum | |

| Plastic | |

| Fiberglass | Acrylonitrile Butadiene Styrene (ABS) |

| Polycarbonate (PC) | Acetal (Polyoxymethylene (POM)) [Delrin] |

| Polyetherimide (PEI) [Ultem] | Polyvinyl Chloride (PVC) |

| Polypropylene(PP) | Polyether Ether Ketone (PEEK) |

| Polyethylene (PE) | Polymethyl Methacrylate (PMMA/Acrylic) |

| Polyurethane (PU) | Polytetrafluoroethylene (PTFE) [Teflon] |

| Part size | Tolerance |

| 0-12"/0-304.8mm | 0.001”/0.0254mm- 0.005"/0.127mm |

| 12"-24"/304.8-609.6mm | 0.010"/0.254mm |

| 24"-36"/609.6-914.4mm | 0.015625" (1/64)/0.397mm |

| 36"-60"/914.4-1524mm | 0.03125" (1/32)/0.79375mm |

| Over 60"/1524mm | 0.0625" (1/16)/1.5875mm |

All CAD files ready for review can be uploaded for quoting (STEP, IGES, STL acceptable)

Surface finish set according to customer's requirement.

1. usual is : Ra3.2 / 125 uin/3.2um. Parts are left with visible tool marks and potentially sharp edges and burrs

2. Polishing: Could up to Ra0.2

3. Powder Coating: sprayed onto a part which is then baked in an oven. This creates a strong, wear- and corrosion-resistant layer

that is more durable than standard painting methods

4. Electroplating: Gold or Black Zinc Plating, Galvanizing, Anodizing, Chrome, Nickel Black etc.

Machining Gear |

Precision CNC Machining Service |

5 axis Machining Service |

Machining Watch Case Service |

Machining Titanium |

Machining Ceramic |

NC Turning Service |

4 axis Machining Impeller |

Machining Plastic Parts |

3 axis Machining Service |

CNC Machining Flange |

Micro machining |

Machining Copper Service |

CNC MACHINING Quality Control:

Quality inspection report link

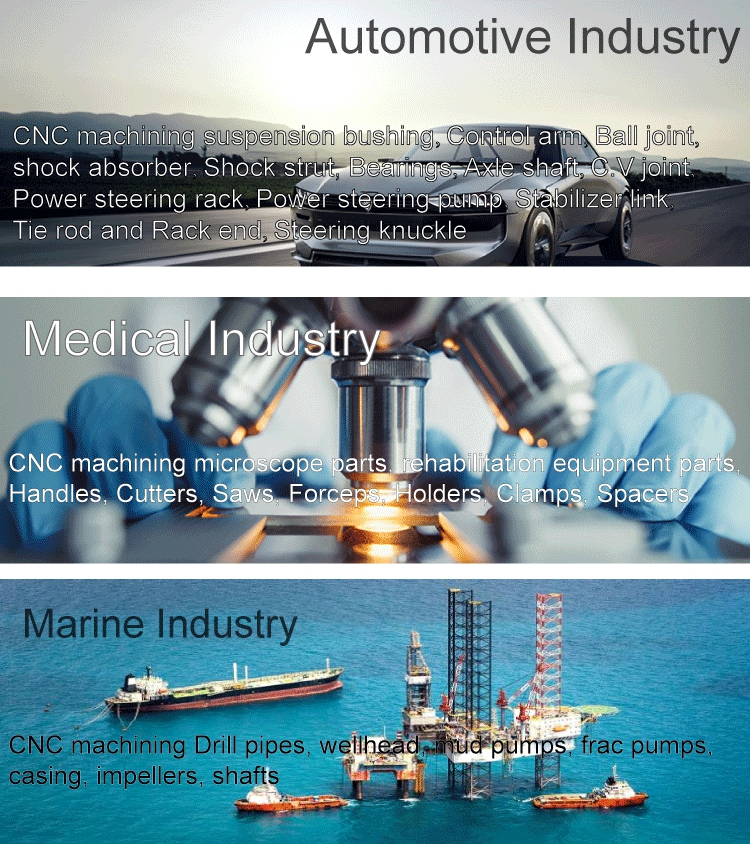

Application:

Product packaging:

Related Products

Custom low friction ...

FlytigerCNC get a order for low friction rings. We thinking it could make a big order in future. So we make this website, to show our low friction rings quality and details. We could customer the ring size, color, logo color, material.

Machining Spinning T...

FlytigerCNC is a mechanical processing factory. we could machining metal spinning top in stainless steel, copper, brass, aluminum, tungsten.

Custom Watch Crown

FlytigerCNC have the professional CNC PRECISION AUTOMATIC LATHE to make the watch crown. customized logo, size , thread, shape.

Custom Recovery Ring

FlytigerCNC offer a strong, lightweight and safe alternative to the traditional metal snatch block.The Recovery Ring can be used wherever you'd need a pulley – for changing direction of a winch line, mechanical advantage or to slow down winching operation