Various cutting methods for laser cutting machines

laser cutting (2).jpg" width="422" height="333" style="width: 422px; height: 333px;"/> laser cutting (2).jpg" width="422" height="333" style="width: 422px; height: 333px;"/> | Various cutting methods for laser cutting machines processing method. A laser beam is focused to form a spot with high energy density. Laser cutting mainly has four different cutting methods to cope with different situations. 1. Melt cutting |

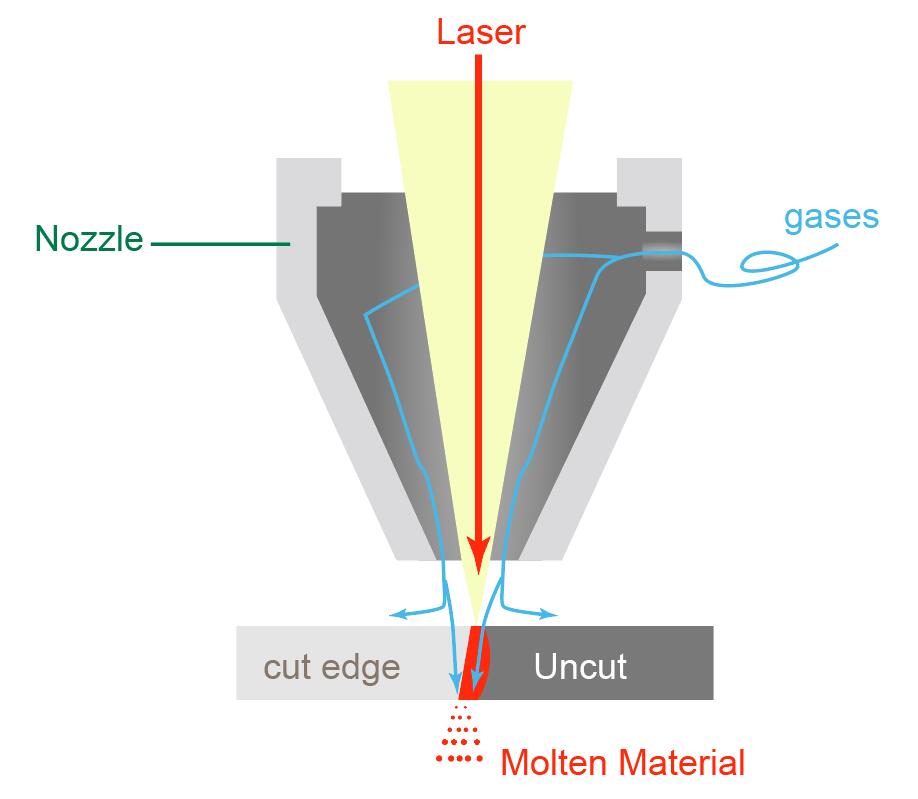

1 Melt cutting

After partial melting, the molten material is removed by means of a gas stream2 Vaporization cutting. The laser beam is matched to a high purity inert cutting gas, forcing the molten material to leave the slit and the gas itself does not participate in the cutting. The energy required for gasification is usually higher than the energy required to melt the material. In laser melting and cutting, the laser beam is only partially absorbed. The maximum cutting speed increases as the laser power increases. Laser melt cutting for oxidized cuts for iron and titanium. Because the inert gas continuously removes the material. So the cutting surface is very bright.

2 Vaporization cutting

During the laser gasification cutting process, the surface temperature of the material rises to the boiling point temperature so fast that it avoids the melting caused by heat conduction, so that some of the material vaporizes into vapor and some of the material is used as the effluent from the bottom of the slit. In order to prevent the material vapor from condensing onto the slit wall, the thickness of the material must not exceed the diameter of the laser beam. Processing is only used in the small field of use of iron-based alloys. This processing cannot be used for wood and ceramics, etc.

3 Controlled fracture cutting

High-speed, controlled cutting by laser beam heating for brittle materials that are easily damaged by heat.

4 Oxidative melt cutting

The material is ignited by irradiation of a laser beam with oxygen or other reactive gas, and a strong chemical reaction with oxygen generates another heat source to further heat the material. Cutting speed is faster than melt cutting. However, the quality of the cut may be worse than that of melt cutting. The precision is not high and the surface burrs are many. Need secondary treatment.