| Name: | Custom Laser cutting |

|---|---|

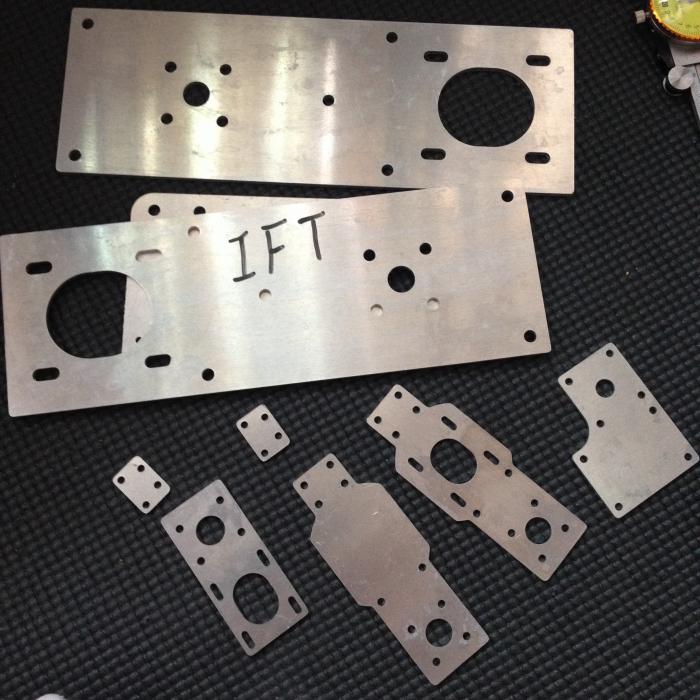

Product Description

Before offer the price. Get the quote simply by completing and submitting the form below:

• Attached 2D or 3D design( We accept IGS, IGES, STP, STEP, SLDPRT, 3D DWG, 2D DXF,PDF, JPG,PNG and more.)

• Material:________

• Quantity: _________________pcs

• And many kinds details. Finishes, tolerance,Hardness and more.

• Where to Shipping: _______________ (Country with postal code please)

| Quickly turn around : Many kinds machines, highly accurate parts in as little as 1 business days. |

| Multiplicities : We could make the welding, 5-Axis Machining, Turning, Chucking, Threading, Milling, Tapping, Drilling, Material Cutting, waterjet cutting , stamping |

| PRECISION: laser cutting offers high-precision tolerances ranging from +/-0.0008″, depending on customer specs. |

| MATERIAL SELECTION : Choose from over 50 metal materials, ceramics, plastics, stones, glass and carbon fiber |

| CUSTOM FINISHES: Anodizing, Plating, Powder coating, Polishing, Painting and so on. |

| Minimum Order Quantity: 1 piece. We believe the customer will place a large order for us after they know our quality |

| One- stop service: we could make the stamping parts, Casting parts, 3D printing etc. |

| Sample: If the sample design is easy making, we could free for you. |

| Engineer : When you bring a design, drawing or concept for a product that you need manufactured, our designers and engineers will make sure that all of the dimensions are right and that the correct materials are used to stand up to the practical applications of the part, tooling or machine you need. |

| After-sales service : If your order or our sales have any dissatisfactions. Please send the email to top@flytigercnc.com. We will reply to you in 12 hours. We Guarantee, if it is our mistake, we will free redo or full refund for you ! |

| Disadvantage: 1. can’t reply in 6 hours every time. 2.Not rich English. Telephone communication is inconvenient. 3.We are not a big company. but we will be. 4.The service is not perfect! |

| MATERIAL |

| METALS |

| Aluminum |

| Brass |

| Bronze |

| Copper |

| Alloy Steel |

| Cold Rolled Steel |

| Galvanized Steel |

| Hot Rolled Steel |

| Tool Steel |

| Stainless Steel |

| Titanium |

Finishing

| Surface finish set according to customer's requirement. usual is 125 uin/3.2um |

| Parts will not be left with visible tool marks and potentially sharp edges and burrs |

| Polishing |

Broaching |

| Powder Coating: sprayed onto a part then baked in an oven. |

| Electroplating, Blue, Gold or Black Zinc Plating, Galvanizing, Anodizing |

Machinery

| Laser cutting Machine |

Laser power 500w, 750w, 1000w, 2000w, 3000w, 4000w

repeat positioning accuracy ±0.02mm