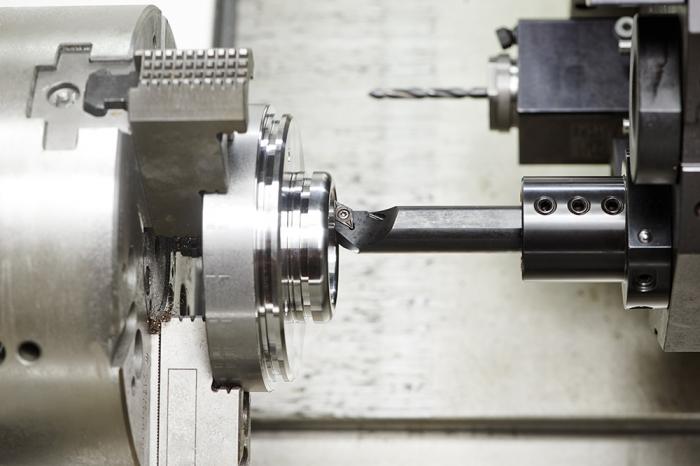

Why does the machining accuracy of the parts decrease?

The accuracy of the CNC machining parts almost determines the quality of the product, and the more precise the parts, the higher the accuracy requirements. Why does the machining accuracy of the parts decrease?

1. When installing the blank, the dynamic error between the shafts is not adjusted well, or because the shaft drive chain changes due to wear and tear will affect the accuracy of the parts. In general, the accuracy deviation caused by this type of error can be solved by re-adjusting the compensation amount. If the error is too large or even if an alarm occurs, it is necessary to check the servo motor to see if the speed is too high.

2. Over-adjustment of the machine during operation will also affect the machining accuracy. It may be because the acceleration/deceleration time is too short, and the change time is appropriately extended. Of course, it is also likely that the link between the lead screw and the servo motor is loose.

3. Since the roundness caused by the two-axis linkage is out of tolerance, the mechanical deformation of the shaft is not adjusted, the pitch compensation of the shaft is incorrect, or the axial positioning is offset, which may affect precision precision parts.

FlytigerCNC's machine are regularly inspected and commissioned every year. All products undergo rigorous quality testing before leaving the factory. Please don't worry about quality!